Hello and welcome back to a new blog post. Today we discuss a question that I received in the context of polymer material selection: How can the flow and chemical resistance of amorphous polymers be improved?

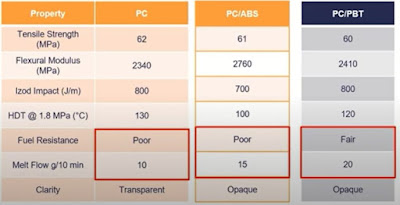

One effective way to improve the flow of amorphous polymers is by alloying them with semi-crystalline polymers. In Table 1 the example of Polycarbonate is shown which is alloyed with ABS and PBT.

|

| Table 1: Blending PC with ABS and PBT to improve flow and chemical resistance |

PC itself has good all over mechanical values and excellent impact behavior. However, fuel resistance is poor and also injection moulding is more challenging. Alloying a PC with ABS results in a material which has better flow properties. Fuel resistance remains at the same bad level. Alloying PC with PBT we can improve both: lifting fuel resistance to a fair level and double the melt flow. You have the toughness of a PC combined with the solvent resistance of PBT. Your product will have good heat, chemical, and impact resistance with good mouldability.

Why are polymer blends useful during the material selection process?

Polymer blends help to fulfill open product requirements since most polymers show a lack of certain properties (flexibility, transparency, low density). Also, lower material costs can be achieved with polymer blends.

Thanks for reading and #findoutaboutplastics

Greetings,

Herwig

Interested to talk with me about your polymer material selection, sustainability, and part design needs - here you can contact me

Subscribe to my Polymer Material Selection book launch page

Interested in my monthly blog posts – then subscribe here and receive my high performance polymers knowledge matrix.

Literature:

[1] https://www.youtube.com/watch?v=nLGcSszTaTs

[2] https://www.youtube.com/watch?v=QrbHcEagUZM

No comments:

Post a Comment