Hello and welcome to a new post. Today we continue with the second part of our plastic additives series. In this post we discuss how fillers change the properties of polymer compounds and how we can use this during material selection.

General effects caused by fillers

Table 1 shows the effects on Elastic-modulus, elongation, toughness, flames resistance, and dimensional stability caused by different fillers such as glass fibers, UV-stabilizers, and flame retardants. UV-stabilizers, flame retardants (organic and inorganic), and anti-statics show a negative impact on the modulus of elasticity, elongation and toughness.

|

| Table 1: overview of effects caused by different additives [adapted from 2] |

Modification of properties by using isotropic, flaky, and fiber shape additives

Now with the know-how of Table 1 it is possible to influence certain properties by using different additive geometries. In general, isotropic fillers have the same behavior in x-, y-, and z-direction and improve the dimensional stability of your final part. Platy shaped fillers are very good in the x- and y-direction however not so good in z-direction. Fibers are only good in one direction and show a fair behavior in the remaining two.

|

| Table 2: overview of property modification by filler geometry [3] |

Example on warpage control of semi-crystalline polymers

In Table 1 and Table 2 we discussed how to improve the dimensional stability of polymers. In this example we have semi-crystalline polymer with a glass fiber loading and we would like to have a better hand on the warpage control of the final part. The glass fiber loading causes a different shrink rate in x-direction than in y-direction leading to warping of the part. If we take a semi-crystalline polymer with isotropic filler loading, shrink rate in x- and y-direction are the same, however the final part will show a low strength. The key is to combine glass fibers with isotropic filler in order to obtain a flat part with good strength properties.

How to do it?

A common compounding solution is to use 15 weight-% glass fiber and combine it with 25 weight-% mineral or beads.

Example improvement of wear resistance of amorphous polymers

In case you consider an amorphous polymer such as Polycarbonate (PC) for applications which need to have a certain level of wear resistance (for example gears), an effective way is to use PTFE as a lubrication additive. This is demonstrated in Table 3, where 15 weight-% PTFE is added to a PC. Both, the wear factor and the dynamic coefficient of friction could be reduced.

|

| Table 3: wear improvement of amorphous polymers |

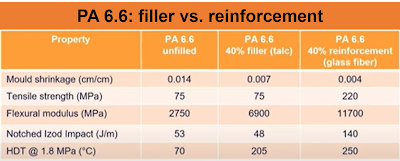

Example Polyamide 6.6 (PA 6.6): filler vs. reinforcement

In general, by using fillers we can have a good shrink control, improve the modulus of elasticity, and heat distortion. Impact resistance will decrease and strength will remain the same. Using reinforcements, strength and modulus will improve, together with heat distortion. Regarding impact resistance, reinforcements will make brittle resins tough and tough resins brittle. Table 4 compares an unfilled PA 6.6 with a 40 weight-% talc filled and a 40 weight-% glass fiber reinforced PA 6.6 to better illustrate the main differences of filler and reinforcement.

|

| Table 4: PA 6.6 - filler vs. reinforcement |

Example POM (Acetal): filler vs. reinforcement

In the next example we have an unfilled POM homopolymer (Table 5) and glass as filler and reinforcement. Filling the POM will increase the tensile modulus, however tensile strength will decrease. Reinforcing with glass by using a proper sizing of the glass which can be coupled to the polymer, tensile strength and modulus can be increased.

|

| Table 5: POM - filler vs. reinforcement |

In the next part we discuss how to improve the conductivity (thermal and electrical) of polymers.

Here you can jump to part 1 and here to my posts on flame retardants, as well as CTI improvement strategies, involving additives.

Thanks and #findoutaboutplastics

Greetings,

Herwig

Interested to talk with me about your polymer material selection, sustainability, and part design needs - here you can contact me

Subscribe to my Polymer Material Selection book launch page

Interested in my monthly blog posts – then subscribe here and receive my high performance polymers knowledge matrix.

Literature:

[1] Gächter and Müller: Plastics Additives

[2] DuPont and Biesterfeld Interowa - Design with plastics, 2011

[3] Chris DeArmitt: https://phantomplastics.com/plastic-materials-training-from-a-top-expert/learn-about-filled-plastics/

[4] https://youtu.be/h7iUC9-JdiU

[5] https://youtu.be/nLGcSszTaTs

[6] https://www.youtube.com/watch?v=1pPx1YbGDBA