Hello and welcome to a new blog post. Today we have a look at the HDT (1.82 MPa) of filled and unfilled amorphous and semi-crystalline polymers.

In a previous post we discussed the HDT values of high performance polymers such as PPS and PEEK. In general the Heat Deflection Temperature or Heat Distortion Temperature (HDT) describes the temperature at which a polymer test bar bends 0.25 mm under a given load and is estimated by the ASTM D 648 or ISO 75. Apart from the DMA, HDT can be used to predict the maximum service temperature of parts under mechanical loads. For this the HDT at 1.8 MPa is used. It can be measured at 0.46 MPa and 8 MPa too.

HDT @ 1.82 MPa of filled and unfilled thermoplastics

Figure 1 shows the HDT values at 1.8 MPa loading for unfilled and filled (30% glass fiber) amorphous and semi-crystalline polymers.

|

| HDT @ 1.82 MPa of filled and unfilled thermoplastics |

Are there differences in the HDT between amorphous and semi-crystalline polymers when they are filled with glass fibers?

Yes, there are differences. Amorphous polymers such as Polystyrene, ABS, Polycarbonate, and Polysulfones show a minimal effect in change of HDT with glass fiber incorporation. However, semicrystalline polymers show large effects and the HDT value can be increased. For unfilled semicrystalline polymers, the HDT is close to the glass transition temperature and the filled version have a HDT close to the melting temperature.

How does the HDT with other fillers such as mineral?

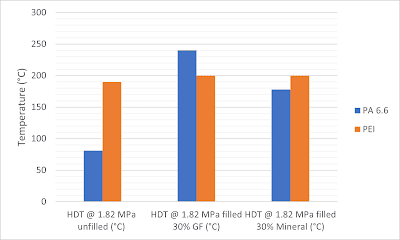

Figure 2 compares the HDT of glass and of mineral filled PA 6.6 and PEI. Mineral filler increases the HDT of semi-crystalline polymers, however not as much as glass fibers. Amorphous polymers show again a lower impact in terms of HDT increase.

|

| Figure 2: Comparison of PA 6.6 and PEI filled with glass and mineral |

This needs to be kept in mind during your part design phase and polymer material selection, especially for technical parts and temperature load, glass fiber reinforced materials can make the difference.

Check also out my UL RTI vs. HDT post here.

Thanks for reading!

Greetings and #findoutaboutplastics

Herwig

Literature:

[1] McKeen - the effect of temperature and other factors on plastics and elastomers

[2] https://www.findoutaboutplastics.com/2021/09/design-properties-for-engineers-ul-rti.html

No comments:

Post a Comment